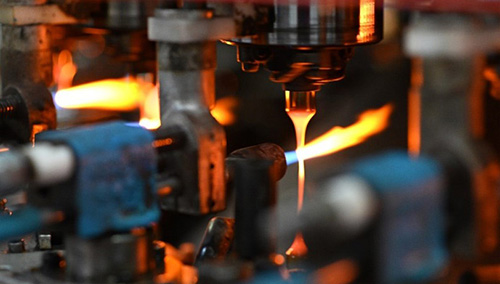

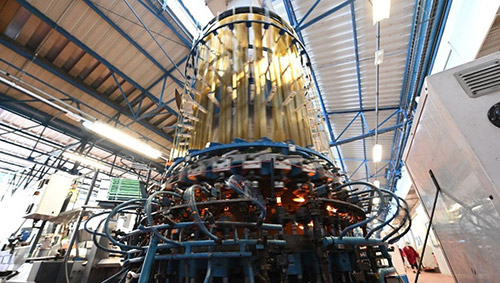

In the same cycle, the cut tip of a glass ampoule (which beaded tip was made in the previous round), and the beaded tip of the next ampoule is made. Thus, we have a start of the tube with only a cut tip, then an end of the rod with only a beaded tip.

Finally, the finished glass ampoules are collected on a conveyor belt for finishing operations.

The know-how of the glass setter consists of dosing the heating of each torch, controlling the strokes and speeds of descent, as well as the speeds of rotation of the machine and the tubes, in order to ensure the dimensional conformity of the glass ampoule and in particular:

- that the shapes of the shoulders, which will allow the filled ampoule to be well hung on its rack (stamped cardboard on which they will be stored in the box), are respected.

- that the diameters of the cut tips are regular in order to allow:

- correct filling by the client laboratory.

- that they can be properly sealed by the customer laboratory after filling.

3. Finishing the glass ampoules, the second stage of the manufacturing process

The various finishing operations are as follows:

- 3.1 Calibration (dimensional control).

- 3.2 Printing.

- 3.3 Annealing.

- 3.4 Self-breaking.

- 3.5 Packaging of glass ampoules.

3.1 Sizing

In addition to the capacity, two dimensional dimensions are essential for a glass ampoule:

- the tip diameter determines the correct filling process.

- the total length determines the correct path of the glass ampoules on the finishing line. The vertical machine sometimes produces short ampoules which, during finishing operations, can get in the way of the line and cause all the following ampoules to fall off, or even damage the printing screen.

These two parameters are automatically checked at the beginning of the finishing line by a “vision device” control system. A digital camera transmits an image of each glass ampoule passing through the line to a microcomputer. Specialized software analyses this image and deduces certain dimensions, which it compares with the limit values supplied to it. This device also makes it possible to check other dimensions than those indicated in the previous paragraph.

The system controls an ejector that removes all out-of-tolerance glass ampoules to a single waste bin, but in return the screen constantly shows the average value of the measured dimensions, the number of rejects and the value measured on the rejected ampoules. It is therefore on the basis of the information available on the screen that the setter makes his corrections.

https://www.sfamgroup.com/wp-content/uploads/2025/04/drug-manufacturing-challenge-pharmaceutical-cdmo.jpg

654

1154

SFAM

https://www.sfamgroup.com/wp-content/uploads/2024/06/logo-sfam.svg

SFAM2025-04-10 09:00:542025-04-10 08:52:05Pharmaceutical CDMOs: key advantages and challenges of pharmaceutical outsourcing

https://www.sfamgroup.com/wp-content/uploads/2025/04/drug-manufacturing-challenge-pharmaceutical-cdmo.jpg

654

1154

SFAM

https://www.sfamgroup.com/wp-content/uploads/2024/06/logo-sfam.svg

SFAM2025-04-10 09:00:542025-04-10 08:52:05Pharmaceutical CDMOs: key advantages and challenges of pharmaceutical outsourcing