https://www.sfamgroup.com/wp-content/uploads/2025/09/eco-friendly-packaging-for-medicines-in-glass.jpg

654

1154

SFAM

https://www.sfamgroup.com/wp-content/uploads/2024/06/logo-sfam.svg

SFAM2025-09-11 17:19:452025-09-11 17:19:45Eco-design and sustainability in pharmaceutical packaging: the role of glass

https://www.sfamgroup.com/wp-content/uploads/2025/09/eco-friendly-packaging-for-medicines-in-glass.jpg

654

1154

SFAM

https://www.sfamgroup.com/wp-content/uploads/2024/06/logo-sfam.svg

SFAM2025-09-11 17:19:452025-09-11 17:19:45Eco-design and sustainability in pharmaceutical packaging: the role of glassProcess and time to market for a drug: key steps and timelines

Bringing a new drug to market is a complex, lengthy, and highly regulated process. The numerous stages of research, development, and evaluation significantly impact the time it takes for a pharmaceutical product to reach patients. For stakeholders in the pharmaceutical industry, as well as dietary supplement manufacturers, understanding the factors that influence these timelines is essential.

Bringing a new drug to market is a complex, lengthy, and highly regulated process. The numerous stages of research, development, and evaluation significantly impact the time it takes for a pharmaceutical product to reach patients. For stakeholders in the pharmaceutical industry, as well as dietary supplement manufacturers, understanding the factors that influence these timelines is essential.

This article explores the key steps involved in bringing a drug to market, how long they take, and the role of manufacturers in working to shorten these timeframes.

1. What is the process to market a drug ?

The process of bringing a drug to market refers to the steps required to obtain authorization to commercialize a pharmaceutical product.

It is a regulatory procedure overseen by organizations such as the European Medicines Agency (EMA) or the French National Agency for the Safety of Medicines and Health Products (ANSM). This process ensures that medications are effective and safe for patients.

A drug cannot be marketed without a specific authorization, known as a Marketing Authorization (MA). Unlike dietary supplements, which follow less stringent procedures, drugs must undergo rigorous clinical trials and thorough evaluations.

To learn more about the MA process, explore our complete MA guide.

2. Key steps in the marketing procedure

Bringing a drug to market involves several stages, each of which can influence the overall time required for its commercialization.

a. Research and Development (R&D)

The process begins with laboratory studies, followed by preclinical tests conducted on cells or animals (in vitro, in vivo). If these tests are successful, clinical trials are carried out on human volunteers in three phases:

- Phase I: evaluation of the drug’s safety on a small group of people.

- Phase II: study of the effectiveness and side effects on a larger group.

- Phase III: confirmation of effectiveness on a larger panel before submission for marketing authorization (MA).

These R&D steps can take several years.

b. The submission of the marketing authorization application (MAA)

Once the clinical trials are completed, the pharmaceutical company submits a marketing authorization application (MAA) to the relevant authorities. This dossier includes the results of the clinical studies, product information, and details on its production process.

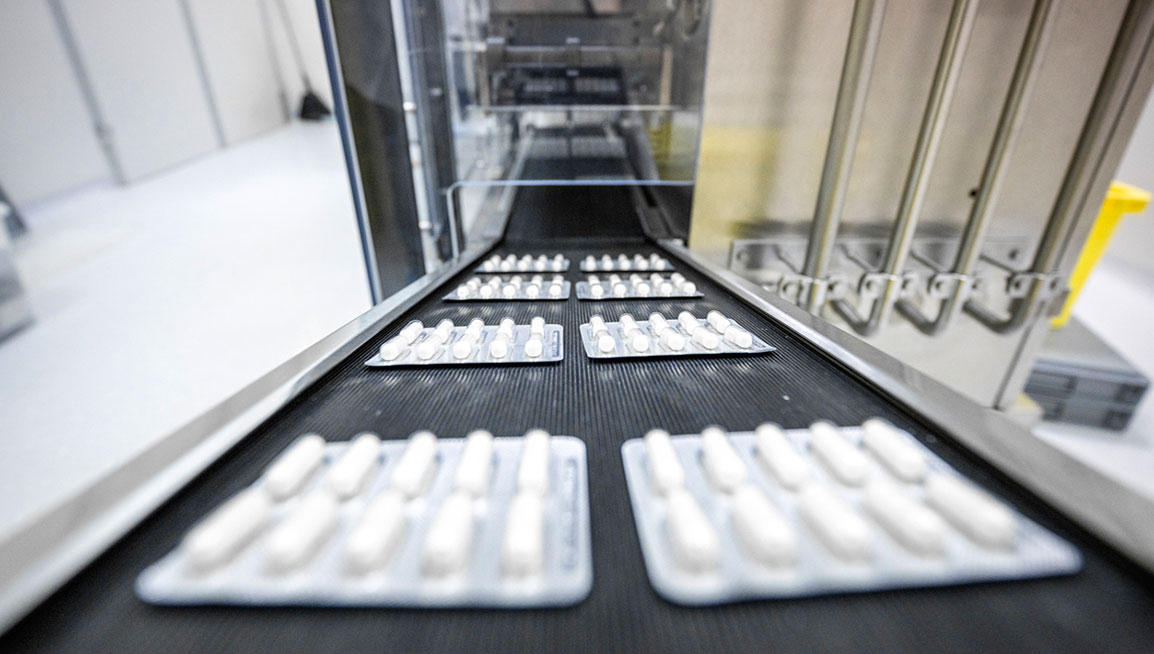

The pharmaceutical manufacturing of drugs is one of the steps in the process of marketing a drug.

c. The evaluation by the relevant authorities

Agencies such as the EMA or ANSM evaluate the marketing authorization application. This process can take several months to a year, depending on the complexity of the dossier and the responsiveness of the pharmaceutical company.

If the dossier is complete and the results are satisfactory, marketing authorization is granted, allowing the drug to be marketed.

3. Factors that influence the time to market

Several factors can lengthen or shorten the time it takes to bring a drug to market:

- Duration of clinical trials: Each phase of clinical trials can take several months or years, depending on the availability of volunteers, interim results, and potential modifications to the study protocol.

- Complexity of product: New molecules or innovative technologies generally require more extensive testing.

- Response time of the authorities: The evaluation and decision timelines of the authorities can vary depending on the workload of the agencies and the quality of the submitted dossier.

- Collaboration with manufacturers: Manufacturers involved in the drug’s packaging process can play a key role in managing timelines.

Our double-tip ampoules are an efficient and safe packaging solution. Discover everything about manufacturing double-tip ampoules.

4. The role of manufacturers in optimizing timelines

Manufacturers of dietary supplements and pharmaceuticals play a crucial role in reducing time to market. By providing innovative packaging solutions, such as SFAM’s double-tip ampoules, they optimize the production process and facilitate efficient timeline management.

At SFAM, we offer double-tip ampoules that enable fast and secure vacuum filling. This patented process allows for an average of 37,800 ampoules to be filled per hour, thereby accelerating the production and packaging stages of dietary supplements and pharmaceuticals while ensuring optimal quality.

In addition, pharmaceutical manufacturers have certifications and rigorous control processes in place, ensuring that every product meets the quality and safety requirements set by the authorities. Thanks to these innovations, companies can reduce the time to market for their products, while maintaining high standards.